The Internet of Things has been of great significance in the modern world. It has been applied in almost every aspect of life, from finances to more critical aspects like our health. IoT has transformed every sector significantly and we previously discussed about how AI and machine learning can make the IoT more powerful. In this article, we shall look at exactly how Industrial Internet of Things becomes advantageous for industries.

Industrial IoT has Improved Operational Efficiency

IoT has played a major role in streamlining the operations in organizations. In the finance sector, for instance, IoT has transformed the customer experience in various ways. Smart Chips have been integrated into products to detect anomalies and alert the manufacturers during the production process. This allows correction early in the production process.

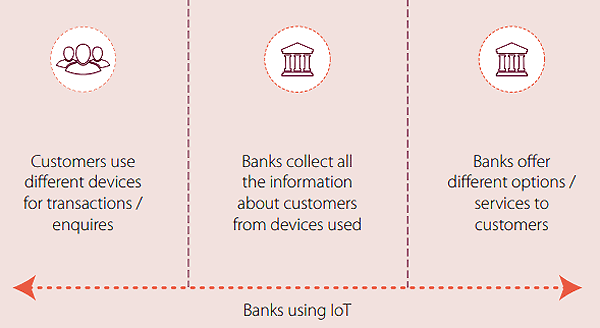

Initially, banking process used to be a lengthy activity involving a lot of paperwork, but with the implementation IoT, the banks collect data from their customer’s devices and offers customized services online.

Machine breakdowns that oftentimes have been a stumbling block in the manufacturing process have been well taken care of. This has been achieved through the use of sensors to collect data and alert the maintenance team of any impending machine breakdowns, consequently ensuring longer operational periods. IoT connects the production systems allowing them to be viewed as one instead of separate systems. This enables easy monitoring.

In healthcare, IoT presence has been felt as well. Inventions such as mobile health technology which helps health organizations obtain vital data through machine learning and predictive analysis. Additionally, the drone technology, a product of IoT, has been used to deliver blood in remote locations during emergencies. This shows that IoT is making operations more efficient in various industries.

Industrial IoT has Ensured Energy Efficiency

IoT plays a big role in ensuring energy is used efficiently. It has been used aversively in energy management. Through controlling energy consumption, IoT has greatly helped in waste reduction that has not only led to cutting down on carbon emissions during manufacturing but also saving on costs. System modernization as well, and minimized human labor has also played a significant role in cost savings.

Through IoT, energy-efficient devices such as smart thermostats have been invented, cutting down on energy waste. Disasters that can be of a devastating impact on energy production have been prevented courtesy of IoT. Companies like the Pacific Gas and Electric Company are using IoT solutions like drones to locate leaks in their energy production process. This has prevented catastrophic occurrences that can be in the form of fires.

IoT enabled systems have also been used to improved efficiency in energy production. For instance, General Electric (GE) has applied this technology to help increase the coal power plant efficiency for up to sixteen percent. This has been achieved through fuel combustion optimization, a process carried out by connected machines that are fitted with sensors that collect data and

Reduced costs from Predictive Maintenance and Wastage Reduction

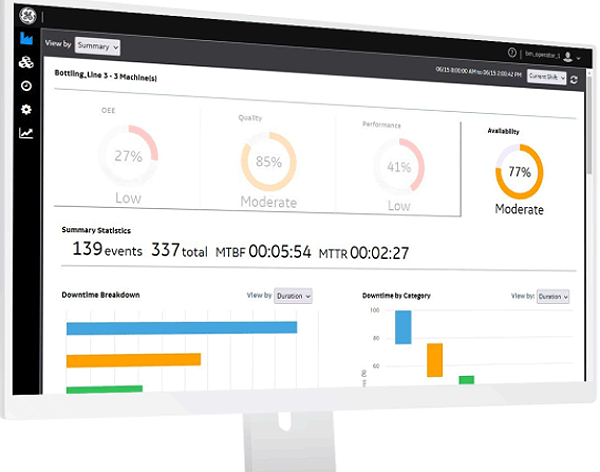

The use of smart machines and devices in manufacturing has improved predictive maintenance as there are no unplanned downtimes. This has been achieved by analyzing the condition of the equipment to predict its failure through constant monitoring. The machine and equipment are monitored when operating normally and incase of any indications that equipment needs repair or attention, the system is alerted.

When using predictive maintenance, operating systems can have measurements on various dimensions of machine operation and conditions, obtain data, analyze it and use the acquired facts to improve the overall application. The sensors collect data regarding temperatures, vibrations, and oil levels among others. The data collected by the sensors within the connected manufacturing equipment is used to predict are which are likely to fail. The right maintenance measures are also predicted to avoid misuse of spare parts. General Electric uses its IoT platform, Predix, to carry out predictive maintenance. Other IoT implementation in the energy sector includes smart grids, smart buildings, and sustainable smart cities.

As for waste reduction, IoT has once again proven to be of great advantage. Various companies especially in the food industry to improve the production and efficiency level. IoT through sensors and smart data processing has been used to maintain ideal storage conditions for perishable raw materials, and finished products to prevent spoilage. These initiatives have helped cut down wastes by up to 23 percent. IoT continues to streamline the production processes and the significant reduction in waste can wholly be attributed to it.

Improved Quality of Products and Services

The use of IoT machines in the production process improves the quality of products. The production process is monitored to ensure the right amount of inputs are used, and the production conditions are optimal to ensure the out meets the expected quality. Companies are now producing better products thanks to highly sophisticated technology. They can produce more high-quality products in a shorter time thanks to mass customization.

Other essential services like car parking in smart cities, for instance, how been automated through technology implemented by IoT. A driver is notified of empty slots within a particular area. This has not only made life easier but also helped save on time.

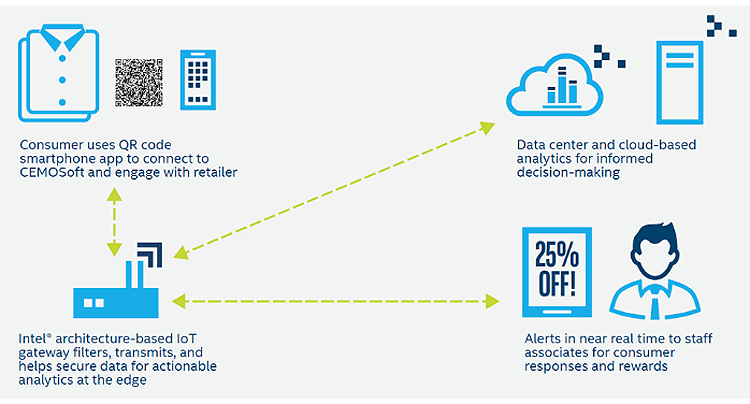

Informed Decision Making from Deeper Performance Insights

Businesses and companies are using IoT to make crucial decisions regarding their products and services. How is this done? Manufactures, for instance, are installing sensors to their products and components so as they can relay back information about how they are performing. This technology can help companies notice a product that is likely to perform poorly and replace it before it causes harm. Therefore, when a company has to decide on such a product, it will be easier considering that they have all the data they need. IoT, therefore, has a hand in the decision-making process. The information acquired about products also enables the company to pinpoint areas that need improvements and the products that can be withdrawn completely from the market.

Image Source Intel.com

Improved Customer Experience

Customer experiences have been improved tremendously thanks to IoT. In hospitality, for instance, hotels are using facial recognition technology to help identify who the incoming customer is before they arrive. Additionally, they are also using sensors and emotion-recognition devices that enable hotel employees to predict when a guest gets hungry and provide meals based on their preferences.

In retailing, the need to move around when doing physical shopping has been eliminated. IoT has enabled e-commerce where people can trade, buy and sell products just from the comfort of their homes.

Conclusion

The advantages of IoT are more than you can imagine. It plays a vital role in almost every aspect of life, from healthcare, manufacturing, retail to finance. IoT, when integrated well, has the potential to deliver even more than we have experienced.